PRINTED ELECTRONICS AND BIO SENSORS

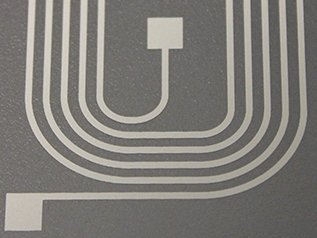

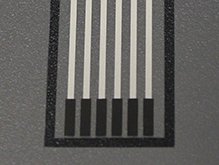

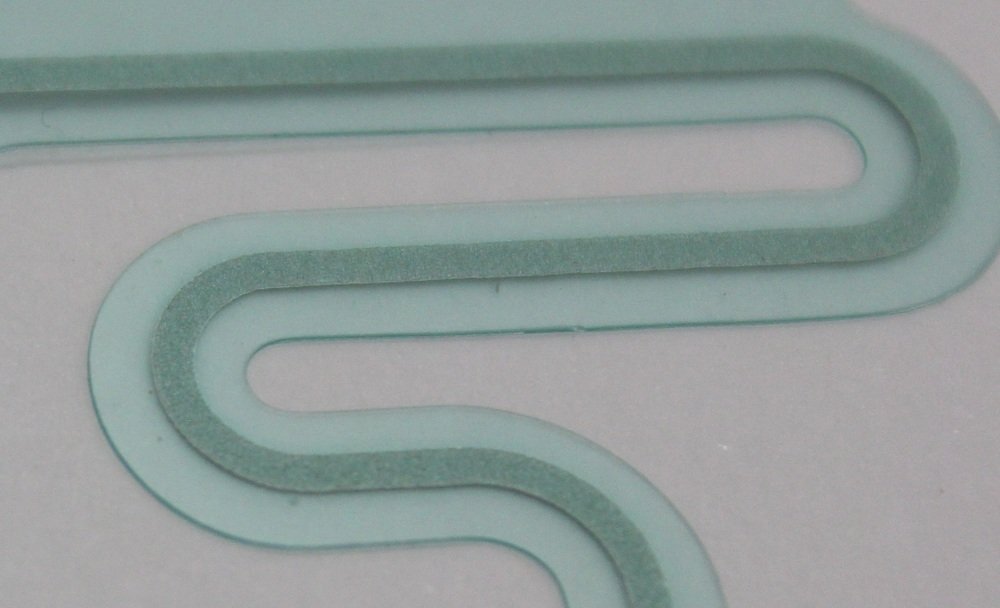

Printed electronics are electrical components and devices produced by a number of printing processes.ECI Technologies uses the screen printing process for all of our sensor and electronic products due to the inherent deposition thickness that can be achieved, which is far thicker than any other printing and deposition process. Screen printed inks and binders are more durable, and flexible in the industry. ECI designers have the ability to work with customers to create specialized coatings and formulas that match the performance requirements of the end user.

PRINTED ELECTRONICS APPLICATIONS:

Bio Feedback – EKG and ECG Sensors

Time release Transdermal Patches

Capacitance Switching Systems

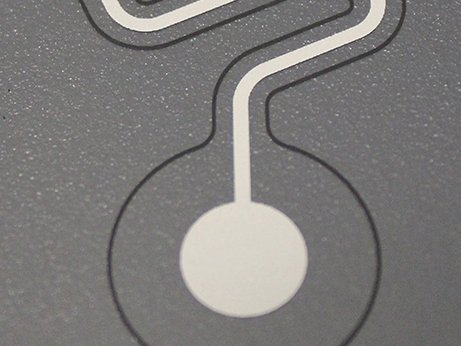

RFID Antennae

Shielding

Batteries

Heaters

Typically these types of devices require development between the materials, process, and end use of the product. ECI specializes in creating Project Teams which will work with Engineers, Doctors, and Designers to facilitate the proper ink/Gel ratio, formulate a variety of conductive pastes, and inks with different loads of additives, or characteristics to develop the final product which can be reliable and viable in Printed Electronic product development.

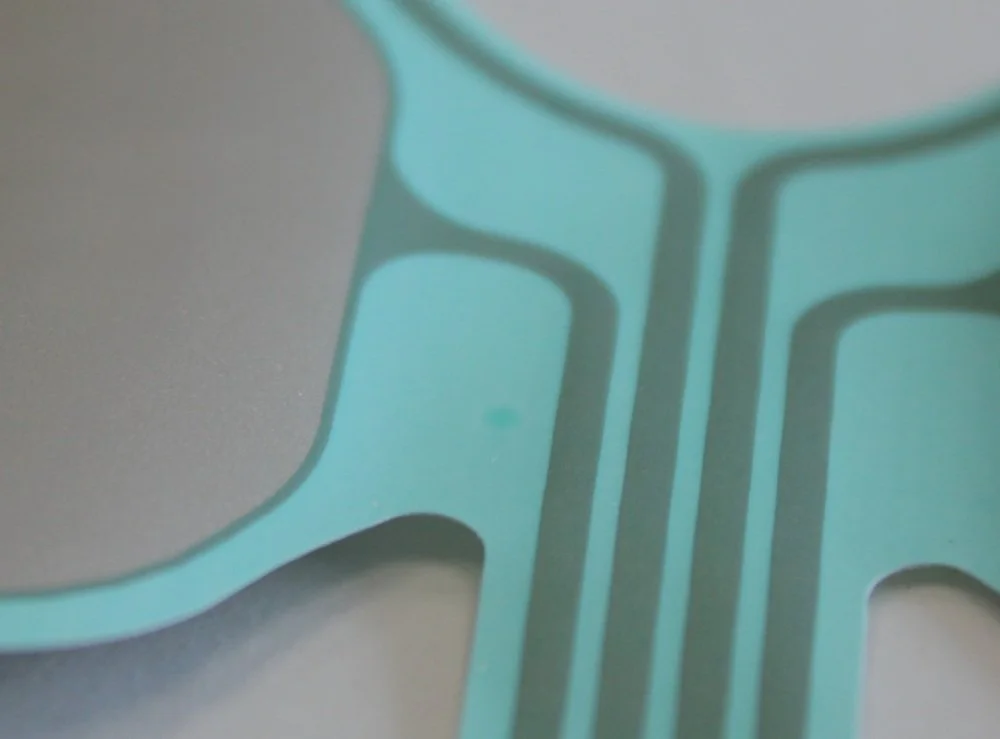

Electrically functional inks are deposited on the substrate, creating active or passive devices, such as thin film circuits, sensors, transistors or resistors. The term Printed electronics specifies the process and can utilize any solution-based material.

One of the most important benefits of printing is low-cost volume fabrication which has opened the door for the medical industry to include electrically functional parts as disposables. Medical electronic products need absolute reliability and printed electronics offer this as well as patient comfort, less invasiveness and can be disposable. The ability to offer remote diagnostics in a cost effective, disposable form is driving the medical industry to develop more and more products based on printed electronics. Moving forward, biosensors such as EKG/ECG electrodes, glucose test strips and pads for drug delivery manufactured by using combinations of silver, silver-silver chloride, carbon, and di-electric inks printed on thin film polyester have become the norm.

The medical industry is not the only group taking advantage of conductive inks. Printed Electronics are one of the fastest growing technologies in the world. Industries such as consumer goods, aerospace, industrial electronics, media and tracking and information products are moving toward this technology. They are moving electronics into places they have never been before and are morphing and improving existing electronics in special ways.

Printed Electronics are changing our world every day and ECI is leading our industry into this “new age”. ECI works in conjunction with a wide array of suppliers and our customers to develop and produce printed electronic solutions for a wide variety of industries.

Combining various printed materials such as Nickel, Carbon, Silver Zinc, Tungsten, Silver/Silver Chloride and others, we work to find the perfect blend of materials for each application.

ECI TAKES YOUR IDEAS AND BRINGS THEM TO LIFE.

OUR EXPERIENCED TEAM UTILIZES MATERIALS AND TECHNIQUES THAT ARE BEST SUITED FOR YOUR APPLICATION AND AESTHETIC REQUIREMENTS. WE CONTINUALLY TEST NEW MATERIALS, PRODUCTS AND INKS IN A VARIETY OF APPLICATIONS TO CONSISTENTLY OFFER THE HIGHEST QUALITY OPTIONS FOR YOU.